SEM Cryo Chamber

The ALTO 2100 system uses a high-stability SEM cold stage with a cooling circuit that is independent of the SEM vacuum and therefore compatible with low vacuum and environmental modes of operation.

Gatan Alto 2100 cryo system consists of:

Gatan Alto 2100 cryo system consists of:

- A two-pot freezing station to produce nitrogen slush and loading pre-frozen samples.

- A vacuum transfer device that enables loading of frozen samples into cryo preparation chamber.

- A dedicated cryo-preparation chamber with an integral nitrogen dewar for contamination-free transfer to the SEM with no degradation of SEM performance.

- A high-stability, gas-cooled, cold stage module fitted to the SEM stage, enabling vibration-free SEM imaging under frozen conditions.

A built in cold knife fracture device

What are the advantages of cryo-SEM over other preparation techniques?

- Cryo SEM is the solution for imaging hydrated, beam sensitive, volatile and low melting point specimens that are normally difficult to image in traditional SEM.

- A rapidly frozen cryo-SEM sample is as close as possible to its natural state.

- Chemical fixation can be avoided. No use of solvents, which can sometimes remove certain sample components.

- No dehydration, therefore delicate structures are maintained without shrinkage.

- Fast freezing means chemical balance is well maintained for microanalysis.

- A soft, volatile or liquid sample is stabilized under the electron beam.

- Materials that are normally soft at room temperature can be fractured under cryogenic conditions.

- Freeze fracture and controlled freeze etching allow optimum exposure of internal microstructure and reveal the dispersion of components and phases in a system such as an emulsion or suspension.

- Cryo-SEM sample preparation time is less than 10 minutes.

SEM Cryo Chamber Featured Images

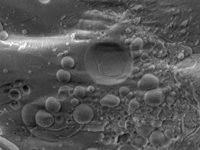

Spinal cord, fractured

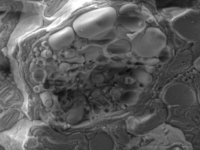

Kidney, fractured

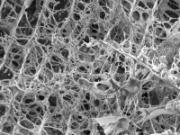

Fibrin hydrogel scaffolding material

(freeze fractured and etched)